Natural

jute

Dubbed the ‘golden fibre’, jute is one of the most commonly used fibres in the world, second only to cotton.

It is a long, soft and shiny fibre with a length of 1 to 4 metres and a diameter of 17 to 20 microns and is one of nature’s strongest vegetable fibres.

The strong threads made from jute fibre are used worldwide in sackcloth and help sustain the livelihoods of millions of small farmers.

Types

of jute

Need more information about our eco certifications?

From field,

to fabric

Jute, which is sometimes referred to as burlap or hessian, is a fibre that is extracted from the jute vegetable plant by hand. This plant is a rainy season crop that takes around four to five months to mature and is harvested every year from June to September.

The process of extraction is called retting and it involves the jute stems being bundled together and immersed in slow running water, then stripped to remove the non-fibrous matter.

The long, silky fibres can then easily be separated and combed into long strings which are spun into yarn at jute mills and later woven in factories to create beautiful jute products.

We procure our jute from India, which is the world’s largest producer of jute, using ethical methods and environmentally-friendly practices.

Why we use jute

It’s recyclable and takes less than two years to biodegrade

It is a fast-growing crop that only takes 100-150 days to grow

The jute industry supports roughly 5 million people in the poorest regions

Our

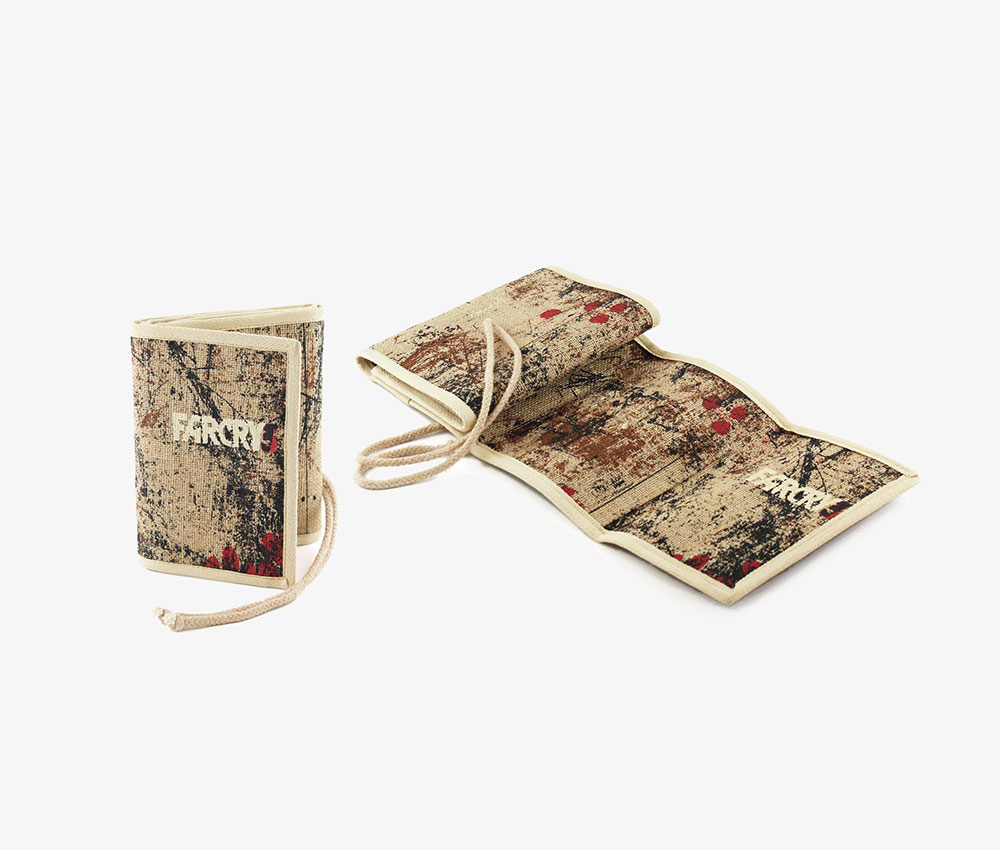

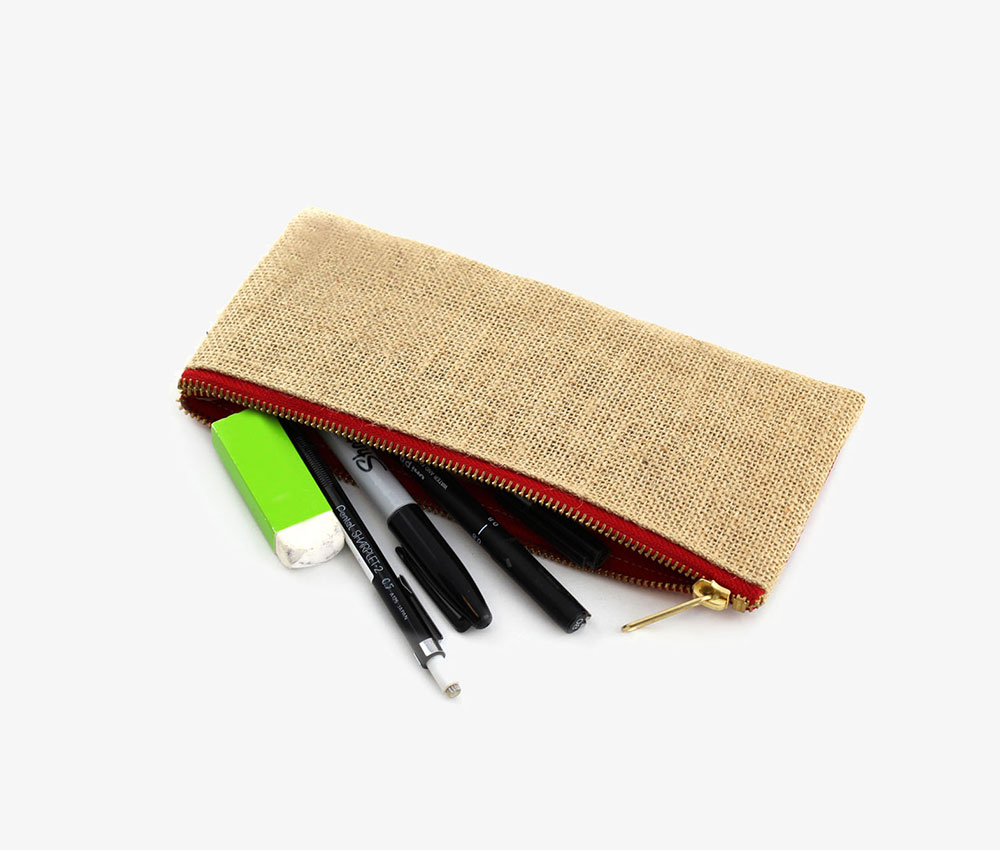

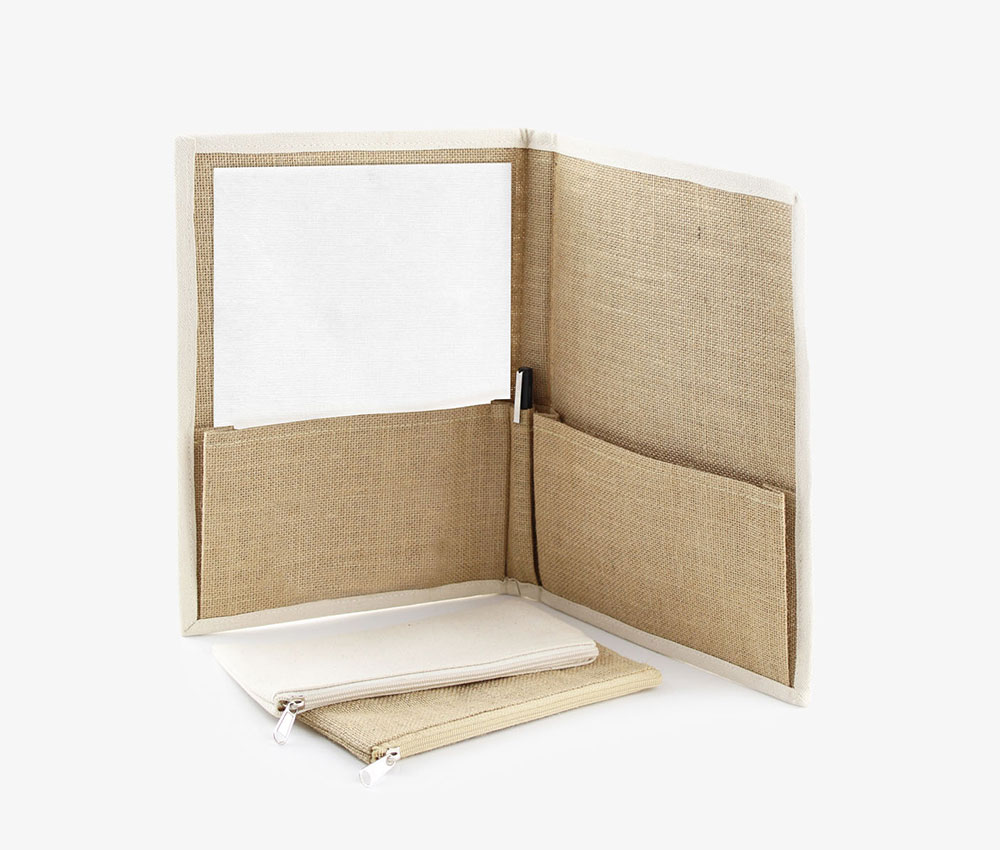

jute products

Are you unable to find the product you’re looking for?

Learn

a little more

Jute cannot be washed as water causes the fibres to turn yellow and, since it absorbs and retains water really well, this will permanently discolour your jute product.

Instead, you must spot clean jute using a damp cloth to remove any small stains or dirt.

The fact that jute cannot be washed makes it an even more sustainable fabric because it requires little maintenance and doesn’t use water or release any microfibres through cleaning.

Jute can be finished with a chemical to create a washed jute (bio-jute) that is able to cleaned and we can supply this type of jute if required.

The weaving process is the method of interlacing the threads of a specific material using two basic components known as warping and wefting. The warp yarns run lengthways and are held tensely in place whilst the weft is drawn through and inserted over and under the warp. Weaves are aimed at enhancing the appearance of the final product and providing a variety of looks and designs so that you can create something that fits a specific purpose or audience.

Jute can be woven in various patterns.

Plain Weave

This weave can take a number of different structures including leno or gauze.

Herringbone

Basket Weave

Matt Weave

Jacquard

Here are the weave counts that we offer for jute.

14x15

11x11

13x13

17x17

10x10

The Pantone colour system is used to typically state the colour to which the fabric is dyed, usually TCX or Solid Coated Pantone references. All our dyes are REACH compliant.

Pigment Dyeing

The process involves giving the jute fibres a positive electric charge to form a magnetic bond with the pigment dye which has been negatively charged. A binder is then added to lock the pigment in place.

Reactive Dyeing

Reactive Dyeing: These are dyes that react with the fibre to form a covalent bond that is highly difficult to remove which means that it is a colour-fast dyeing method. This also means that it is quite expensive but the bright colours that it produces makes it worth every penny.

There are two main steps in the process of reactive dyeing – exhaustion and fixation. Exhaustion is when the bleached jute fabric is dipped into a bath containing a reactive dye and glaubers’ salt where it is left to sit for an hour. Then fixation occurs by adding sodium carbonate to the dye bath – a fixing agent that established the bond between the dye and the fibres.

Finishing, as the term implies, is the final step in fabric production. Hundreds of finishes can be applied to textiles, and the methods of application are as varied as the finishes.

Some finishes change the look and feel of the jute whilst chemical finishes will usually add special characteristics such as fire resistance and scents.

Softening

Calendaring

This is when fabric is sent through heated, pressurised rollers that give the fabric a smooth, lustrous (shine) finish, used for upholstery fabric.

Chemical Finishes

Starch Stiffened: a technique used to stiffen jute so that it holds its shape. A liquid starch is brushed over the surface of the jute or to specific areas that require stiffening.

Fire Resistance: most fibres burn and could be a potential death hazard- by law upholstery fabric has to be treated with a flame-resistant finish.

Washed: this jute has been processed for longer to ensure that it is softer so that it feels more comfortable against the skin. This is ideal for jute apparel and home textiles.

Scented: a chemical that is applied to give the jute fabric a specific smell such as chocolate or roses.

Antimicrobial: an advanced additive that is built into the fabric to inhibit the growth of harmful microbes by up to 99.9%.

Water Repellent: finished with a chemical that makes the jute resistant to water so that it can be used for sand bags and building materials.

Rot Proof: jute naturally decomposes at a fast rate so a rot resistant jute is necessary for creating roofing and building materials

Waxed: waxed jute is typically used to make twine as it enables the material to catch fire easily and safely.

You can add your artwork or branding to jute products using one of these professional printing techniques.

You can add your artwork or branding to jute products using one of these professional printing techniques.

• Screen Printing

• Heat Transfer Printing

• Digital Printing

• CMYK Printing

• Foil Printing

• Tonal Printing

• Embroidery

Did you know?

The jute plant requires 5 – 8cm of rainfall a week, and more during the sowing period

Jute is a feeder crop that adds nutrients back into the soil improving the land for the next rotation of crops

On average, jute plants grow to a height of 10 – 12 feet (3 – 4 metres) before being harvested